During the early stages of the COVID-19 pandemic, staffing restrictions and logistical issues caused dysfunction for supply chains that had never faced obstacles of this magnitude before. Infosys Consulting reported that 57 percent of global supply chains encountered at least a 25 percent dip in operations because of new health regulations. Now, a precarious geopolitical situation threatens to throw gas on the flame.

How is geopolitics affecting the availability of semiconductors and chips?

International trade is rarely seamless. Tariffs, embargoes, and complex import/export regulations complicate an already tricky (and constantly changing) network of international relationships. In particular, tensions between the United States and China strain the already-taxed supply chain, as both countries strive for technological superiority over the other. Gartner, Inc. called it the “Silicon Cold War” in August of 2020, and things have only intensified since then.

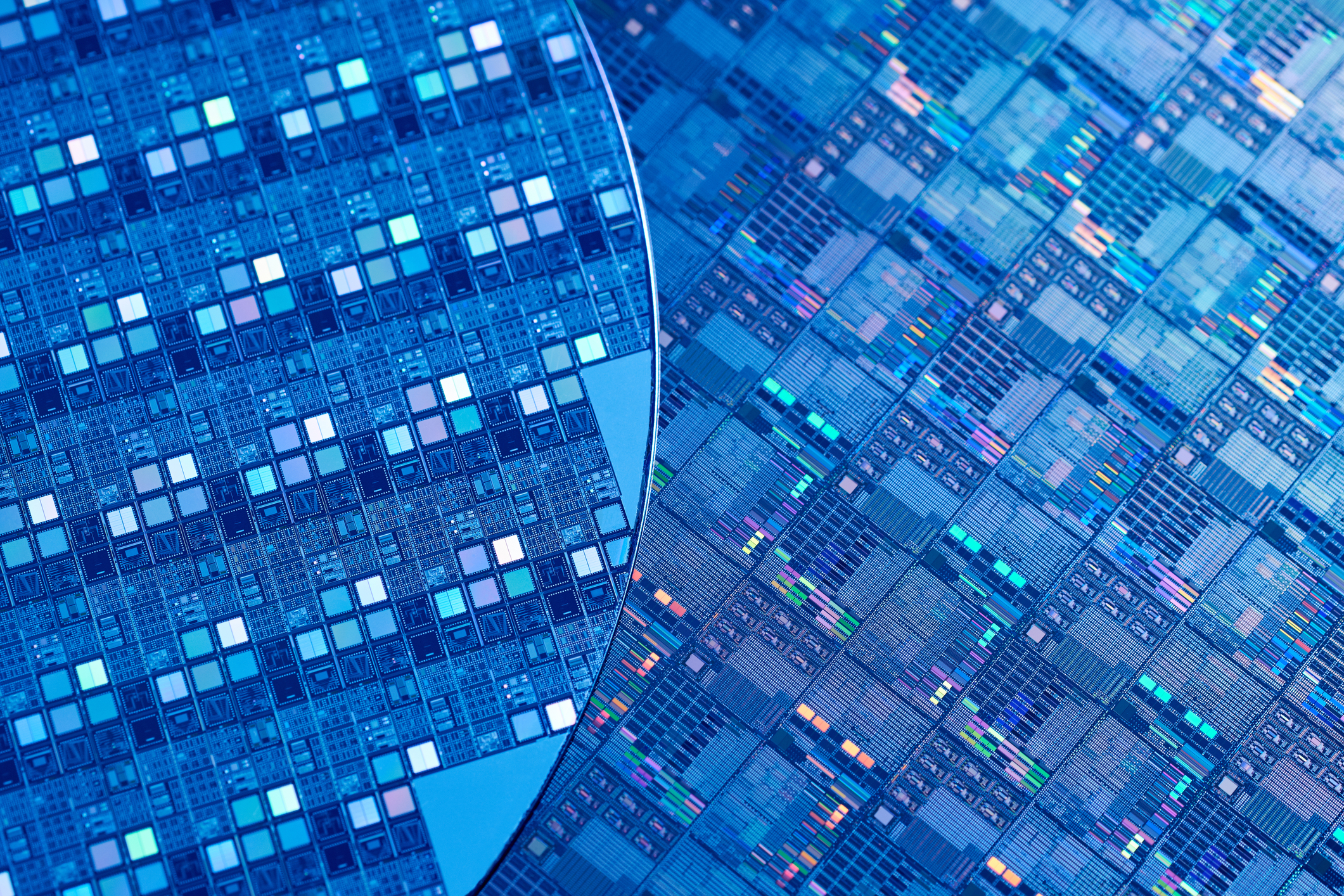

In recent years, China has taken the electronics market by storm, propelling itself to the forefront of production for many well-recognized electronics brands. At the same time, the United States leads the pack for semiconductor production, commanding 48% of the market share and eight of the world’s largest semiconductor companies as of 2020.

China relies on the U.S. for its imports of semiconductors, while the U.S. relies on China for its imports of assembled electronics. In the battle for electronics dominance, the United States has restricted China’s ability to import semiconductors. In response, China fired up its own plans to produce semiconductors.

China is pouring billions of dollars into its own Semiconductor Manufacturing International Corporation (SMIC)–a company that has already been blacklisted by the U.S. While China struggles to catch up, its electronics companies are suffering. In turn, U.S. equipment companies have fewer options for businesses they can contract with, and consumers have fewer options for purchasing electronics.

What is next for the semiconductor industry?

Experts warn that a crisis may be looming. The shortages affect much more than laptops and cell phones; manufacturers of cars, health equipment, and nearly all other industries that use chips are finding it difficult to get the supplies they need to meet demand.

Countries including Japan, India, and Australia also face trade restrictions with China and must scramble to build alternate supply chains for the minerals used in semiconductor production. Until they are successful and until the United States ramps up its own production of electronics, international corporations and consumers alike will continue to feel the squeeze.

However, there is a light at the end of the tunnel. Phoenix, AZ and Austin, TX will soon be home to a semiconductor plant and a Samsung plant, respectively. Both plants should be operating by the end of 2023. With enough time to rebuild supply chains and establish additional semiconductor fabrication plants on local soil, the industry as a whole will eventually find relief. SDS remains dedicated to finding solutions that help your business succeed, even when the going gets tough.